Service

Nordic Tank serves the entire life cycle of a tank vehicle: from design to service life. Our repair assessment service works in cooperation with insurance companies in the event of damage. Contact us if you need factory-level modification or damage repairs, periodic inspections or chassis replacements.

In addition to the manufacture of tank vehicles, we carry out other workshop work and special products according to customer needs, from stainless steel and aluminium, especially for road traffic and rail equipment. Our welding work is standardized according to ISO 3834-2:2005, the welding of rail subassemblies is standardized according to SFS-EN 15085-2:2020 with qualification level CL1, and all of our operations meet the requirements of the ISO 9001:2015 quality system.

Tank repairs, pressure tests and periodical inspections

For transport equipment, we carry out basic overhauls of tanks and tank trailers, demanding collision repairs, ADR inspections, periodic inspections, pressure tests, interim inspections and annual maintenance in factory conditions. In addition to the factory service in Oulu, our service network serves in Perstorp, Sweden.

Workshop services

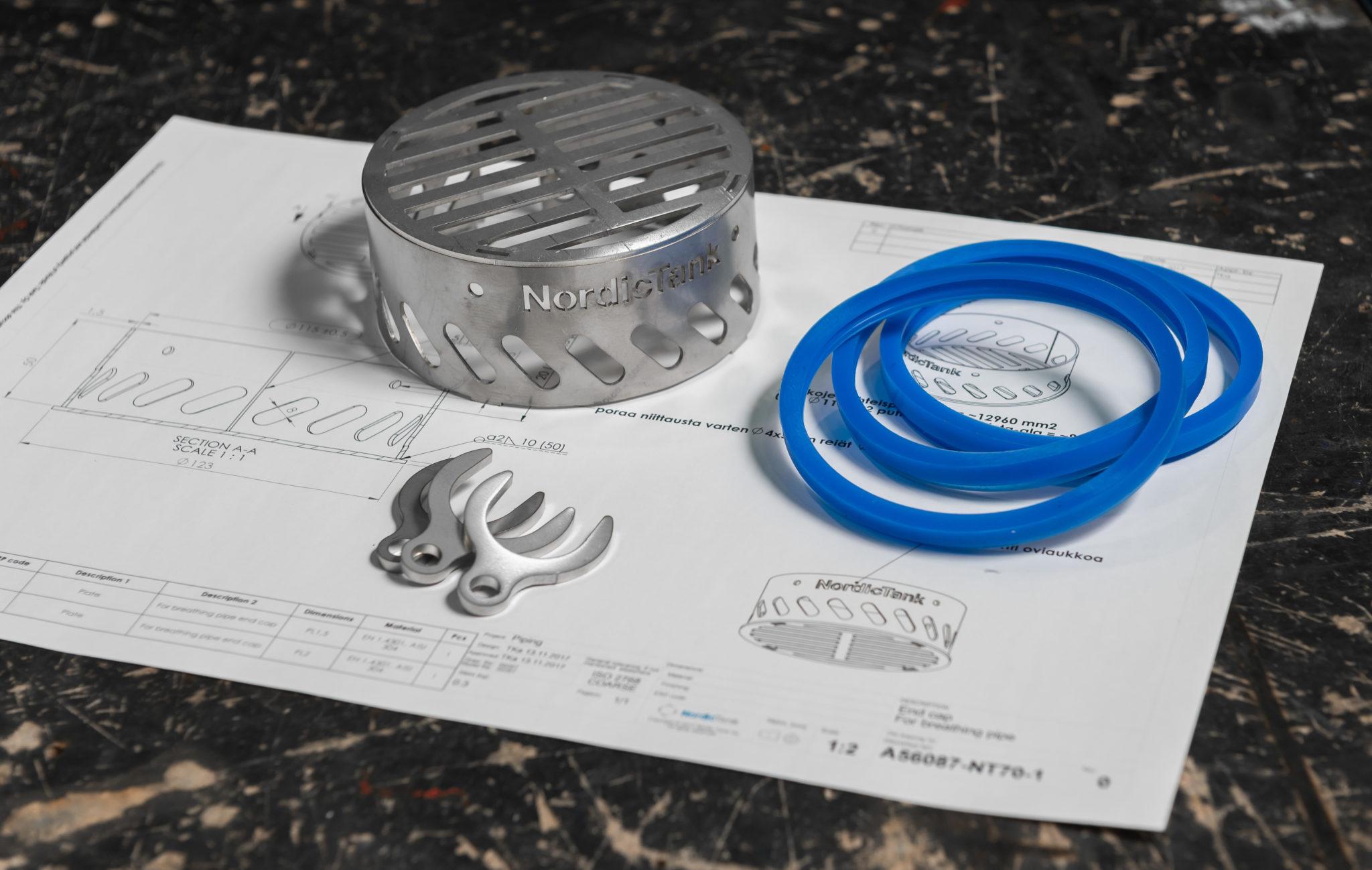

We also offer our stainless steel welding expertise as a subcontractor service – especially for the transport sector. We manufacture parts, components or assemblies to order according to the needs and drawings of our customers, or by participating in the design of both road and rail vehicles. In particular, the welding of subassemblies of rolling stock is standardized according to SFS-EN 15085-2:2020 at qualification level CL1.

Spare parts

We have a comprehensive range of spare parts in stock; not only seals and Nordic Tank spare parts, but also Fort Vale tank components as well as parts for the most common trailer equipment. If you do not find a suitable part from our spare part collection, we can manufacture the appropriate components for you – even for older tanks.

Modifications and refurbishments

We carry out demanding modifications and renovations at our factory with professionalism. For example, axle additions, changes in tank volume, and replacement of surface sheet metal and insulation extend the life cycle of old tanks and offer a cost-effective solution for upgrading equipment.